LIFE CYCLE SERVICE

LAND FIELD

Support for building and industrial electrical plants and

systems throughout the full lifecycle of the equipment

INDUSTRY / ENERGY

INDUSTRY/ENERGY

Servicing Support

Versed in servicing support during industrial equipment

and system installation and product warranty periods

Teratec provides meticulous servicing support for products supplied to customers by our parent company Terasaki Electric Co., Ltd. As their engineering wing, we swiftly respond to specification changes during the installation process and any problems that arise during the product warranty period (1 year unless otherwise specified). We also report customer demands, expectations and improvement work to Terasaki, which they use to hone technologies and enhance the quality of their industrial systems and breakers.

Major locations where we operate

- Domestic/Abroad Infrastructure (Factories, buildings, etc.)

Field Work

- System commissioning

- As the first step to ensuring electrical plants and systems and mechanical equipment operate safely, we carefully check that equipment has been installed and wired as per drawings and diagrams, and operates as intended.

- Performance testing

- We carefully check that important protective, control and monitoring systems and equipment operate correctly and assuredly in the actual environment where installed.

- Test-runs and tuning

- We carefully monitor and tune equipment operating status during system and equipment test-runs.

- Training in operation and handling

- We explain the technical fundamentals and operating procedures of electrical plants and systems to equipment managers and operators. These training tutorials assist the customer in their work safety efforts by laying out example scenarios of potential and unlikely troubles, and highlighting the dangers of human error. The content of the tutorials can be tailored to customer request.

- Improvement work related to specification changes

- It can happen that specifications are changed before plant/system commissioning because of equipment size and quantity increases. We devise the best way to swiftly and properly perform the improvement work without impacting the installation process.

INDUSTRY/ENERGY

TECHNICAL SERVICE

Technical services for industrial electrical plants and systems across the entire equipment lifecycle

We provide customers with technical services for their industrial electrical plants and systems across the full lifecycle of the equipment from commissioning to decommissioning.

Customers

- Engineering companies, heavy electrical equipment manufacturers, dealers and trading companies

Basic Maintenance Plan Proposals

- We propose checks and maintenance plans for important equipment and systems according to the number of years they have been in service. (We additionally scrutinize consumable parts and include a parts replacement plan if needed.)

- Final drawings and documents of equipment delivered by our parent company Terasaki Electric Co., Ltd., and specifications and records of changes and improvements to important equipment and systems are managed and used to support the customer in their efforts to maintain and manage equipment over its full lifecycle.

- Equipment and system integrity are diagnosed and evaluated using checklists that are created from equipment field data and inspection know-how.

- We welcome consultation requests regarding checks and maintenance of medium voltage equipment and relays of other manufacture.

Lifecycle Technical Support Proposals

- We can propose viable periods for prolonging equipment updates based on the number of years of continuous maintenance performed on equipment and systems, the number of years that equipment has been in service, and customer budgets.(Co-generation systems, medium-voltage power panels, low-voltage power panels, panel -internal electrical parts, etc.)

- We are also versed in new technologies, and can swiftly and fully service and improve the performance of the latest equipment and systems.

- Work plans for equipment updates are formulated in consideration of foreseeable restrictions (duration of system downtime, work performed during equipment operation, etc.).

- We will also explore the possibility of updating unserviceable or discontinued equipment and systems of other manufacture with products by Terasaki Electric, and build workable proposals.

INDUSTRY/ENERGY

Maintenance

Making full use of sensorial perception,

data and tools in maintenance

Maintenance work for industrial electrical equipment, plants and systems is mainly classified into “status monitoring” and “scheduled” maintenance. Both are forms of preventative maintenance. This former relies on the customer monitoring the status of operating equipment and systems while they are running. It involves keeping an eye out for strange sounds and odors, pinpointing fault locations if trouble occurs, tracing and recording the process of events that lead to failures, watching process readings in particular situations and their trends, and a lot of other observation tasks when electrical and mechanical equipment and systems cannot be stopped or powered down. On the other hand, this latter is performed at a predetermined time (schedule), which allows equipment and systems to be stopped or powered down for detailed inspections and overhaul (factory-wide or building-wide inspections, etc.). At Teratec, we make full use of the sensorial perception we have honed over the years, data and tools to perform maintenance to the customer’s wishes.

Major locations where we operate

- Domestic/Abroad Infrastructure (Factories, buildings, etc.)

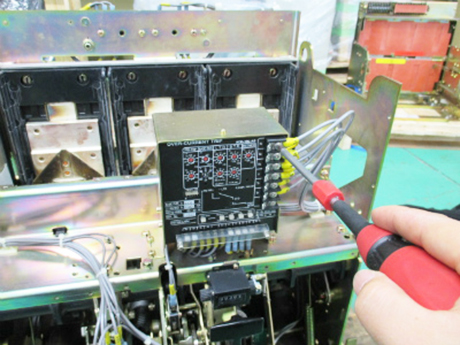

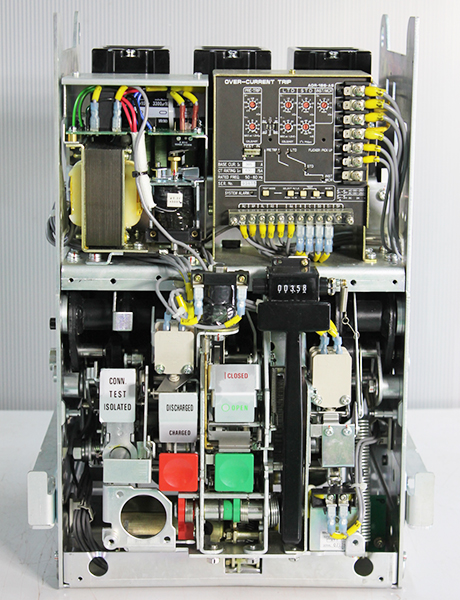

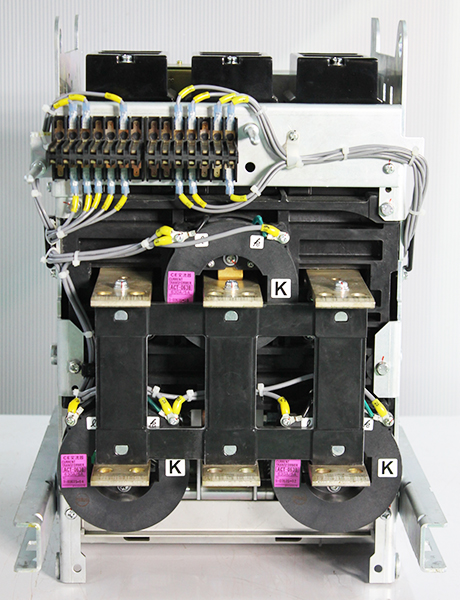

Checks & Servicing

- We compile specifications of installed equipment and systems, records of checks, servicing, repairs and improvements, and other management data as a basis for performing checks and servicing across the full lifecycle of the equipment. Then, highly seasoned servicemen use this data, technical know-how and management criteria from the equipment manufacturers to accurately check and service the customer’s equipment and systems.

- In addition to equipment checks and servicing in the field, we offer equipment overhauls that enhance running stability and prolong equipment service-life at our service shops.

Repairs

- We compile specifications of installed equipment and systems, records of checks, servicing, repairs and improvements, and other management data as a basis for performing checks and servicing across the full lifecycle of the equipment. Then, highly seasoned servicemen use this data, technical know-how and management criteria from the equipment manufacturers to accurately check and service the customer’s equipment and systems.

- In addition to equipment checks and servicing in the field, we offer equipment overhauls that enhance running stability and prolong equipment service-life at our service shops.

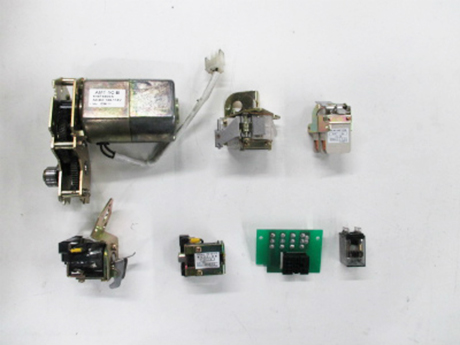

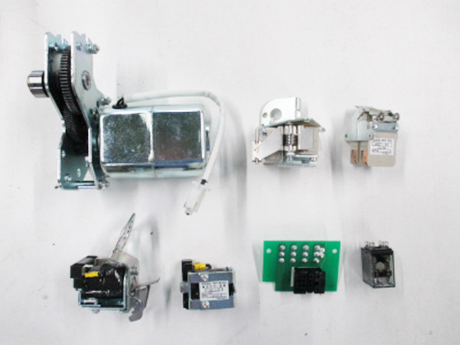

overhauling

old parts taken by overhaul

change new parts

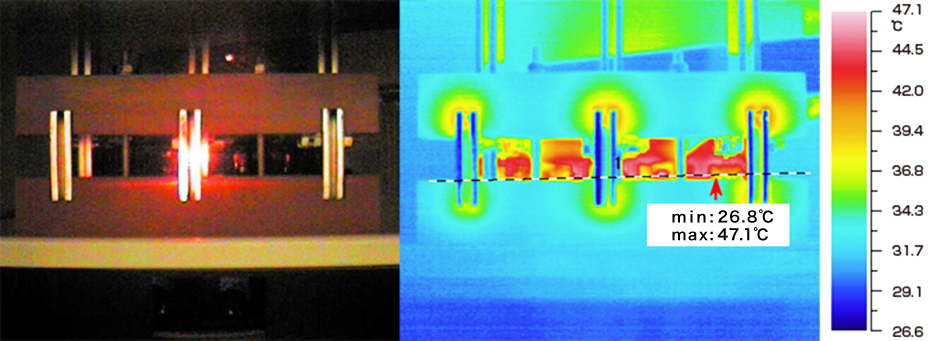

Analysis & Diagnosis

- By analyzing the safety complications due to electrical and thermal stresses in the running state, we can prevent troubles caused by deterioration and aging, and plan out suitable maintenance schedules.

- Use of thermographic imagery

- Conventional maintenance is performed with the target equipment powered down, but some troubles can only be detected, analyzed and diagnosed with circuits in the live state. We, therefore, introduced thermographic analysis and diagnosis in order to reduce the risks of unexpected trouble.

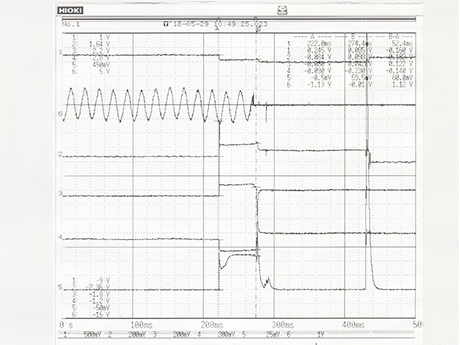

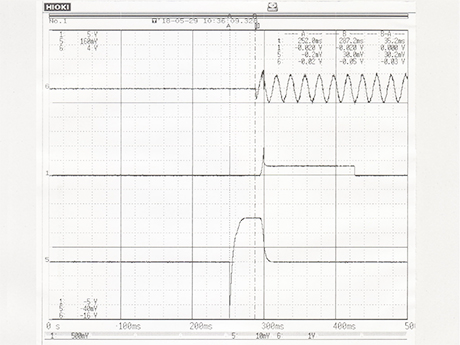

- Analysis of current flows by digital data recorder (MEMORY HiCORDER)

- Our service teams use the latest digital data recorders that reproduce voltages, current flows and signals as visible waveforms, to project current flows inside of equipment as numbers and graphs from which aging and deterioration can be analyzed.

-

Specification Changes & Improvements

- Electrical plant and mechanical equipment upgrades, specification changes and improvements can trigger necessary specification changes for electrical distribution, control and monitoring equipment (circuit breakers) and systems. Teratec can swiftly make the required improvements on-site, by putting together the best work method and flow for the job.

power distrbution panel due to specification changes Before

After

INDUSTRY/ENERGY

Troubleshooting

Scrambled support for trouble during equipment operation

If a customer incurs trouble in their electrical distribution and control systems or equipment (circuit breakers) during operation, we scramble our support teams. Right from the get-go, the sales, design, field support and quality assurance departments at Teratec work as one to repair and restore equipment to guaranteed levels of safety and performance. If trouble occurs in a factory, building or at some other infrastructure site in Japan or somewhere around the world, service teams from our offices or members of the TEAM TERASAKI Global Service Network race to the site in order to repair and restore equipment in the least amount of time possible.

Major locations where we operate

- Domestic/Abroad Infrastructure (Factories, buildings, etc.)

Example service calls

| Category | Checkpoint | Trouble | Hint | Remedy |

|---|---|---|---|---|

| Malfunction of spring charging means (Mechanical) |

Cracking | The feed lever did not advance the ratchet because of cracking in the lever holder’s caulked portion (Spring charging disabled). | Cracking is highly probable because the lever is frequently operated, therefore check the caulked portions for cracking. | Replace the the feed lever holder (with caulked portion) on the lubrication diagram M1. |

| Damaged spring | Spring charging was disabled because of a damaged M-spring in the feed lever. | Damage is highly probable because the lever is frequently operated, therefore check the M-spring for damage. | Replace the side M-spring of the feed lever on the lubrication diagram M3. | |

| Wear | Spring charging was disabled because of wear in the feed lever (moving/stationary sides) and ratchet (teeth). | Check feeding tooth by tooth for the charging handle. | Replace the stationary side of the feed lever on the lubrication diagram M1. | |

| Replace the moving side of the feed lever on the lubrication diagram M3. | ||||

| Replace the ratchet on the lubrication diagram M3. |

We look at each checkpoint without exclusion to judge exactly what needs fixing.※Please scroll horizontally and see.

Troubleshooting

workflow