LIFE CYCLE SERVICE

MARINE FIELD / LAND FIELD

RETROFIT /

RENEWAL

RETROFIT

RETROFIT

marine and industrial circuit breakers (ACB / MCCB)

3-in-1 performance,

precision and safety improvements by proper retrofitting

Periodic maintenance is effective towards using electrical equipment and systems safely over long periods of time. Still, electrical equipment can last only a determinant number of years. As a guideline on circuit breaker replacement, the Japan Electrical Manufacturers’ Association (JEMA) recommends changing out breakers every 15 years or a specified number of ON-OFF cycles. At Teratec, we can replace or retrofit aging circuit breakers with ACBs and MCCBs at the right time.

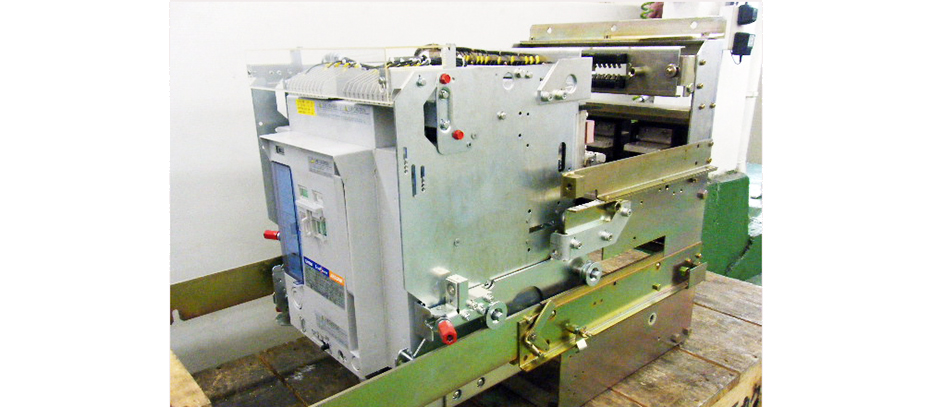

ACB Retrofitting

Teratec retrofits old ACBs with the latest models so that electrical systems are up-to-date with this critical protective device.

before

after

The way of ACB retrofitting

If thinking about retrofitting your electrical systen with an ACB, it is also important to consider, in addition to the costs, the amount of time required for work and the duration of the resulting power outage.

At Teratec, we will propose the best approach based on the customer’s existing equipment (marine/industrial, purpose, etc.) and wishes.

"Attachment type" ACB retrofitting

"Auto-coupling type" ACB retrofitting

Workflow for ACB retrofitting

STEP.01

Preliminary discussions & Estimate request

In order to prepare an estimate, we discuss the job with the customer and hear their explanation of things.

Preliminary matters

We confirm the specifications and purpose of the customer’s existing ACB,

note other priorities they have and request their support and necessary considerations for a field visit.

Teratec

(Sales, Engineering, Service)

Preparation of retrofitting proposal

We explore ways to retrofit the target equipment and systems,

based on the information provided by the customer and equipment dealers,

and what we learned from our field visit.Field visit, preparation of basic drawings (draft),

selection of the best equipment/materialsExtraction of field risks, calculation of work period and man-hours

Determination (necessary/not necessary) and calculation of power outage time, preparation of requests for the customer

- Retrofitting proposal

- Estimated price, work period, man-hours, workflow,

work requests for other contractors, summary of requested items, etc.

STEP.02

Prior to an order being placed

We submit a “Retrofitting Proposal” to the customer.

Meeting with the customer, equipment dealers and other companies (engineering companies, shipyard, etc.) involved in the project

(To discuss the suitability of the Retrofitting Proposal)

STEP.03

Once the job is ordered

We proceed with planning and verifying the details, and procuring parts/materials.

Teratec

(Sales, Engineering, Service)

Preparation of detailed designs (Shop drawings, changes to as-completed drawings)

Procurement of equipment/materials

Finalization of retrofitting workflow (Time frame, personnel, layout, etc.)

STEP.04

Work start

After coordinating the work schedule and plan with the customer and equipment dealers,

we start work at the designated location.

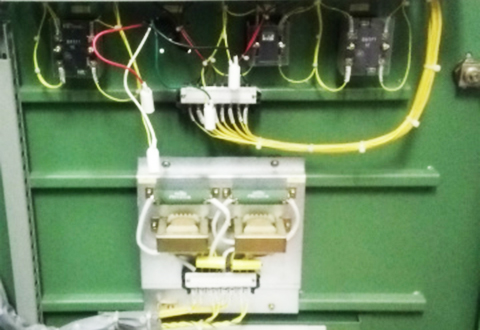

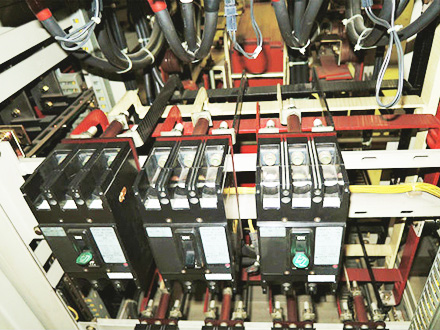

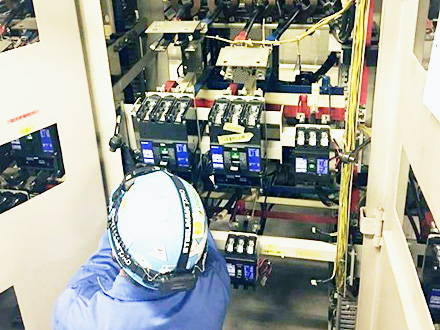

MCCB Retrofitting

In the same manner, Teratec retrofits old MCCBs with the latest models so that electrical systems are up-to-date with this critical protective device.

RENEWAL

RENEWAL

Marine and Industrial Power distribution, Control and Monitoring Panels

Replacement support for power distribution, control and monitoring panels that delivers performance, precision and safety improvements

To extend the service-life of a ship or building, we strongly recommend replacing the power distribution, control and monitoring panels with the latest models because of the enhanced safety, reliability, operability, performance and maintainability they offer. Also worth considering is the fact that internal parts for these panels are hard to come by when a ship or building has been in service 20-plus years. Teratec will propose the best replacement plan in terms of timing and cost-effectiveness in consideration of the remaining service-life of the ship or building.

Renewal

Marine and Industrial System Products & Circuit Breakers

Replacement support for ship/building subsystems that delivers performance,

precision and safety improvements

Automated equipment at the core of monitoring and control tends to lose its performance edge as internal component age over time. If the capacity loss goes as far causing misoperation or malfunction, entire systems could be seriously impaired. Moreover, internal parts for this equipment are hard to come by when a ship or building has been in service 15 years or more. Teratec will propose the best replacement plan in terms of timing and cost-effectiveness in consideration of the remaining service-life of the ship or building.

Control and Monitoring Panels(WE&TERANET)

before

after

Control and Monitoring Panels(WE&TERANET)

Programmable Logic Controller (PLC)